AI in logistics is more than a trend and bigger than the adjustment to the world that is steadily becoming digitized. Driven by the incredible expansion of eCommerce and the rise of international trade, it proves that the old way of handling supply chain operations will impair their efficiency, while the hyper awareness of every operation thanks to real-time tracking can bring it to the next level. McKinsey & Company echoes these words: the consulting company discovered that implementing AI-enabled management has allowed early adopters to improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%.

We invite you to explore real-life AI use cases in logistics and see for yourself whether the technological shift is worth the risk.

written by:

Anton Rykov

Product Manager

Contents

The Magic of Artificial Intelligence (AI)

The power of big data analytics can be safely considered an equivalent of the Hogwarts magic. Isn't it miraculous to dive deep into company insights and predict future demand, reduce transportation costs, automate routine tasks, and improve customer satisfaction? Though no swish and flick took place, and it's the exponentially increasing computing power that we should thank for the opportunity to move forward, what AI technology offers does sound like a fever dream. For instance, as MarketSplash reports, it was estimated that if logistics companies incorporated AI tools into their operations, they could generate annual revenues ranging from $1.3 trillion to $2 trillion over the next two decades. This seems too good to be true, yet we have every reason to believe this is exactly what awaits us in the logistics sector.

There are many ways to apply AI in logistics, especially considering the fact that there are different forms of this technology. For instance, in logistics, we have automation AI that helps with warehouse automation (e.g., order processing and fulfillment, robotics), conversational AI (chatbots for customer service), predictive AI (data analysis, forecasts, and maintenance), generative AI (content generation like reports and future trends, i.e., demand predictions and route optimization). And although we listed a few examples for each AI branch, we don’t mean to say it’s just that one branch that handles them.

All AI forms work in synergy, they constantly and closely intertwine. So, for the sake of everyone’s eye health and sanity, in this article, we’ll take a look at the picture of AI forms in logistics in general. Additionally, there are so many ways in which AI serves the industry, that if we were to talk about each of them separately, we would have to print the article as a separate book. Hence, here, we will dedicate our attention only to demand forecasting, supply planning, predictive maintenance, and delivery route optimization (examples, benefits, statistics, and use cases are below!). Trust us: even that will be enough to discern how the global AI in logistics market size valued at USD 7.96 billion in 2022 can be anticipated to reach USD 238.89 billion by 2031, growing at a CAGR of 45.93% during the forecast period (2023–2031) (Straits Research).

Demand Forecasting

The market these days is overfilled with all sorts of propositions, and the fight for the customers' attention is brutal. Who has everything they want in stock? Who can deliver what they need the fastest? On top of that, the number of goods on offer is beyond what a human can count single-handedly — let alone process vast amounts of the discoveries and build assumptions as to what will have its momentum in the future. With customer demands fluctuating and the market growing, the need for a system revamp became evident. AI solutions gracefully stepped forward with predictive analytics fueled by accessible valuable insights. Through the analysis of historical sales data, social media updates, market trends, and other most significant contributions, logistics professionals saw how quick and effortless demand prediction can be.

As the name suggests, demand forecasting is all about how you can foresee which items will be sought after in the days ahead and how customer behavior can disrupt supply chains. It inevitably contributes to:

- better inventory management that will a) cover future demand; b) allow to plan ahead to decrease the market cost (e.g., the cost fluctuates depending on the season);

- low risks of running out of stock;

- cost reduction resulting from sensible distribution of resources (i.e., you are not spending money and human labor on filling local warehouses with products that do not strike a chord with customers).

Additionally, as Precedence Research reports, “artificial intelligence-powered demand forecasting methods have significantly lower error rates than traditional forecasting methods”.

What benefits does AI in demand prediction unfold for logistics companies?

Resilience of the entire supply chain

Your readiness for anything will make the supply chain bulletproof. Potential disruptions like natural disasters or sudden changes in consumer behavior will not affect it.

Workflow efficiency

A smart chief industry officer does not dedicate time, finances, and manpower to processes that lead their business nowhere. Priorities become clearer and receive your undivided attention, making warehouse operations run smoother.

Business growth

Business expansion highly relies on how accurately you predict demand. With all the right goods stocked in your warehouse, you can move forward with confidence.

Identification of new market opportunities

You can spot the changes in customer expectations early on and come up with new products and services to match them before everyone else. Better quality outcomes include increased revenue and profitability.

Customer satisfaction

If your business can give buyers what they want exactly when they need it, you will win over their loyalty and impress them with a superb customer experience.

Use case: Amazon is an industry thought leader that doesn't need an introduction. This retail colossus leverages AI to the extent that they are able to forecast not only the products that will be favored, but also anticipate orders before buyers even place them. On top of that, demand prediction helps the company to remain prepared for unexpected shifts in customer needs. As Forbes writes, “When toilet paper sales surged by 213% at the height of the COVID-19 pandemic, Amazon used AI-driven predictive forecasting to respond quickly to unforeseen demand signals and increase adaptability to market fluctuations. Freshwater [Jenny Freshwater, vice president of Traffic & Marketing Technology at Amazon.com, and former VP of Forecasting] notes, “Of course, we could have never anticipated that spike prior to COVID-19, but our models reacted quickly to the new demand trend.”

Supply Planning

Supply planning is a process of comparing demand forecasts with existing inventory and performing logistics operations to align the stock with the demand. Analyzing data that goes into that is too complex for a human brain: it wasn't built to digest big data, especially real-time data. It's fantastic that AI systems can perform tasks like that instead. But why exactly does supply planning exert a major influence on in the industry?

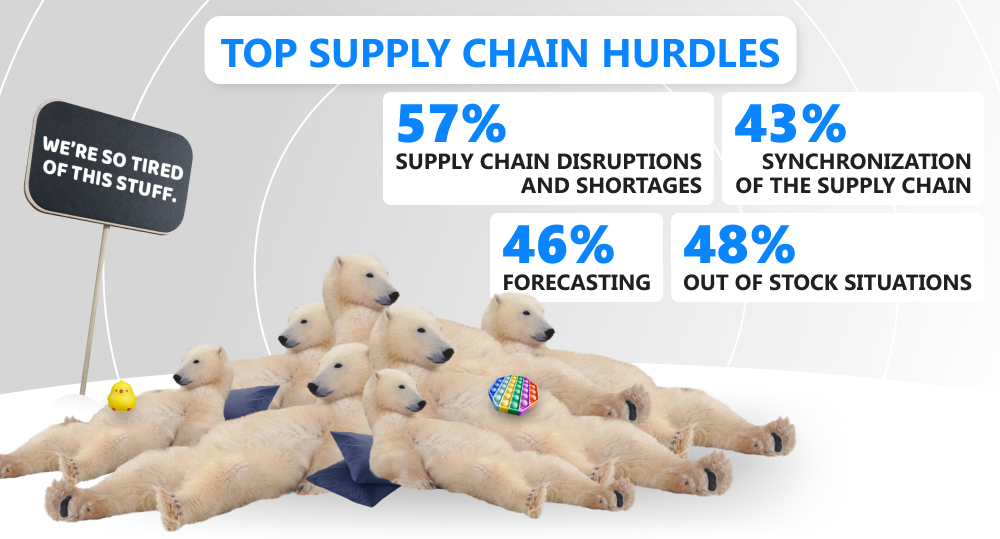

This source states that in 2021, participants of the survey cited the challenges below as top supply chain hurdles:

Succumbing to the challenges like these year after year leads to drastic financial and reputational consequences when businesses lose money at a terrible scale, which can easily drive you out of the market for good. So while it might appear that supply planning is merely the tip of the iceberg that can get short shrift, in reality it is the cornerstone of success. If you don't have the right goods at the right time, who's going to buy from you?

Apart from risk management, if you fully utilize AI in supply planning, it can impress you with such stellar bonuses, as:

- Real-time inventory tracking. Use technologies like frequency identification (RFID), Internet of Things (IoT) sensors, and barcode scanning to instantly receive accurate information on stock levels across various locations, identify anomalies and potential bottlenecks (e.g., shipment delays), and mitigate risks before the situation takes an unpleasant turn.

- Automatic supply replenishment. AI can weigh in all the facts and provide valuable insights within a fraction of a second. It has the ability to evaluate demand patterns, storage capacity, and other indicators to automatically generate replenishment orders. Optimized inventory levels result in the elimination of stock outs and missed sales opportunities.

- Supply chain transparency. Demand prediction and real-time monitoring let AI tap into the intricacies of supply chain relations. High workflow transparency improves communication with suppliers, and all parties work in sync making fewer errors, while orders are closed faster and more smoothly.

Want to hear more about the enticing offerings of AI? See the benefits below!

Structured data

No human can brush up big data, but for AI that's more than feasible. Use it to improve data quality for reports and make informed decisions.

Cost efficiency

Quick access to stock levels and demand patterns will save you from overstocking (which also results in wastage) and understocking. Due to it, you will also be able to decrease storage and shipping costs.

Customer loyalty

With order fulfillment running like clockwork, customers' hearts will belong to you regardless of the season or the time of day.

Happier employees

If you eliminate frustrating routine tasks from the workflow, your team will get ample room to apply their skills in a significantly more creative and impactful way.

Use case: Walmart, a retail giant, utilizes AI to plan supply across thousands of stores, fulfillment centers, and distribution centers. Their AI models learn from every interaction with a customer and apply that data to craft even more satisfying shopping experiences for their clientele, whether they're shopping online on a regular Tuesday or visiting a store during a Black Friday sale. “Our AI-driven systems leverage a variety of factors to determine both quantity and timing of inventory flow, as well as more precisely identify where we distribute, — the company says. — With greater accuracy in our geographic distribution zones, we can understand our customers’ demands down to differentiations by zip codes […] With state-of-the-art learning systems, we are also adding inputs to help adjust for regional differences in needs, cultures, and buying habits.”

Predictive Maintenance

It is a branch of predictive analytics that focuses on proactive methods of addressing maintenance operations. It concentrates on two things: 1) what can happen if current conditions change; 2) what can happen if current conditions remain unaltered.

The logistics industry is unimaginable without machinery and equipment, and artificial intelligence does a perfect job of keeping its hypothetical eye on their condition (system logs, performance metrics, historical patterns, and so on). AI builds patterns to recognize anomalies and notify workers that it's time to take action (i.e., perform maintenance) rather than put it on the long finger and deal with drastic consequences later. FYI, industry studies show that an hour of downtime can cost your company an average of $10,000 to $22,000 (and you don't need that). All in all, any logistics professional, be it a warehouse owner, a terminal operator, or a fleet manager, will find a good friend in predictive maintenance and the digital transformation that follows.

What exactly can predictive maintenance analyze? Pretty much anything. Here are a few examples:

- It can carry out a vibration analysis to trace changes in vibration frequencies of your equipment. Such alterations can be a sign of out-of-shape shafts and loose mechanical components. Your conveyor belts and forklift will thank you for recognizing this in advance!

- AI technology can perform infrared thermographic to detect whether there's heat coming from your warehouse equipment, which indicates a breakage.

- Motor circuit analysis is yet another thing that artificial intelligence does. The technology measures the motor's voltage, current, and other parameters to recognize ground faults or contamination.

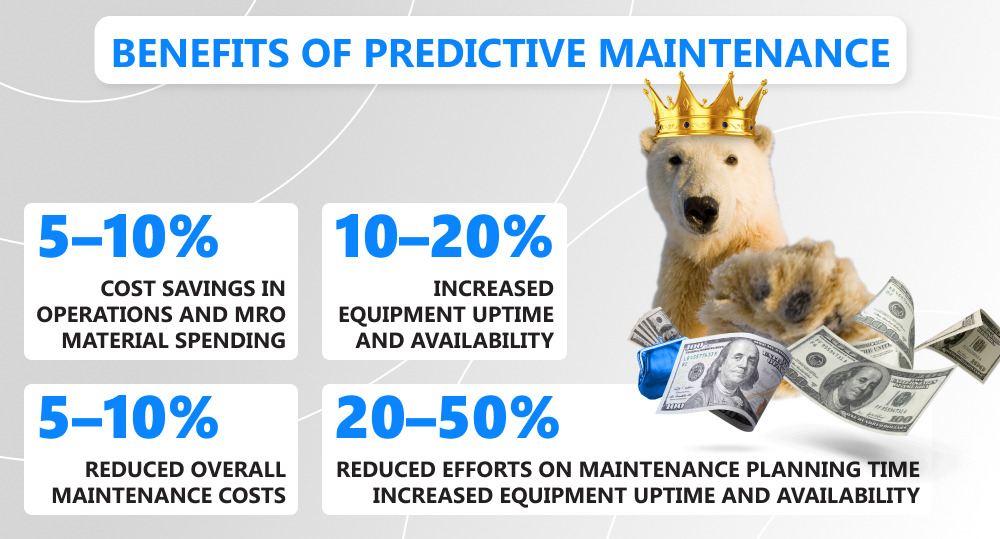

Also, we cannot skip the statistics part. Take a look the numbers from a Deloitte report:

As MarketSplash explains, converting the above percentage rates to real dollars, with predictive maintenance, organizations are expected to save up to $630 billion by the year 2025. And if the numbers are too cold and hard for you, and you're still curious about the benefits of predictive maintenance in logistics, check out the table below:

Safe working conditions

When all equipment functions properly, emergencies are less probable. This results in a positive work environment that has a massive impact on the workflow efficiency and quality of logistics operations.

Reduced operational costs and downtime

Plan maintenance ahead and stay in control of your business. Avoid sudden and costly disruptions, like the work process coming to an abrupt halt or the need to purchase new, expensive equipment while your company loses money.

Prolonged lifespan

Timely maintenance extends your equipment lifespan, which means you can spend less money on what ensures the functionality of your business and produce more revenue.

*By the way, if you want to discover more about the benefits of AI in logistics, find out how logistic regression in artificial intelligence works, or hear about our natural language processing (NLP) projects, write to us! We offer a wide range of logistics development services and will be glad to schedule a meeting with you.

Use case: In 2020, Deutsche Bahn, one of the world's leading providers of transportation and logistics services, developed a diagnosis and analysis platform, DIANA, to perform digital maintenance of switches. As the company wrote, “over 40,000 turnout drive sensors are connected to DIANA. Every day, the platform receives over 1 million turnout cycles and status information. DIANA continuously measures and analyzes the condition. Predictive maintenance is thus made possible – this reduces delays, because switch failures are one of the main reasons.”

Deutsche Bahn enjoyed the results of their experiment: in July 2023, they partnered up with KONUX to equip another 3,500 switches and crossings with KONUX Switch, a predictive maintenance system. The source writes that the solution can forecast “how the condition of certain switch components will develop over time, allowing early intervention and avoiding failures while optimizing maintenance planning. The project volume amounts to double-digit million euro.”

Delivery Route Optimization

According to Research and Markets, the route optimization software market size is expected to grow from USD 3.52 billion in 2023 to USD 5.45 billion by 2028, at a CAGR of 9.16% during the forecast period (2023–2028). The significant advancements of the route optimization sector are the outcome of the steadily increasing demand for elaborate transportation management systems, which is something that both customers and businesses crave.

We talk about route optimization when the business creates the most efficient and cost-effective routes. Optimization here doesn't necessarily mean “finding a route that's shorter than what we originally planned.” It might be the case, but it's still time, fuel, driver schedules, the number of stops, vehicle capacity, delivery windows, and other things of the sort that take precedence in supply chains.

Route optimization is a mathematical problem, so it uses machine learning algorithms (like graph analytics) that process historical data as well as current traffic sensors, GPS tracking (road closures or accidents), and weather conditions (snow and rain affect the speed of delivery) to build the most efficient route for logistics trucks. With the help of real-time traffic data, artificial intelligence can calculate the best route for both manual and autonomous vehicles.

Here are a few fun facts about route optimization (Upper Route Planner):

- The speed of delivery affects 87% of online buyers’ purchase decisions.

- Route optimization has the capability to lower fuel costs by 20%.

- American commuters spend an average of 41 hours per year stuck in traffic. In 2017, traffic congestion in the US was estimated at USD 305 billion, or USD 1,445 per driver.

- Despite traveling 20,000 miles annually on average, fleet vehicles only spend 10% of their time driving. This creates room for considerable cost savings and enhanced productivity via route optimization.

With all that in mind, let's take a look at the benefits that route optimization is ready to offer:

Delivery productivity

Accomplish more with fewer trucks, higher workflow speed, and increased safety for drivers.

Reduced costs

Fuel costs decrease, and so does the amount of driver wages to pay.

Customer satisfaction

Full transparency of the shipping process and control over last-mile delivery will result it in an outstanding customer experience.

Use case: DHL, a global giant in the logistics sector, uses forecasting and prediction models to determine the volumes of shipments that are going to arrive at a particular facility on a particular day with 90–95% accuracy. In such a way, AI systems assist transportation personnel in planning the couriers’ routes, matching volumes, service, etc. “Once the packages are in the delivery vehicle, we then further optimize the route using AI-powered software from Wise Systems. In just a few seconds, it can take a route with 120 stops and order the sequence based on parameters such as an urgent medical express delivery, or a delivery that must be with a customer before 9am…” As the delivery vehicle approaches the customer, they receive a notification with a more specific delivery window. Even if the truck is 20 minutes away from the customer, they can still adjust the delivery spot and time. Only artificial intelligence is capable of such agility, and that agility is what gives DHL clients the top customer experience.

AI-Okay: Final Words on AI in Logistics

The use of AI in logistics does come with its challenges. People often associate the shift with high costs and the difficulty to find the right digital talent to perform more complex tasks. And while it is true, in the case of artificial intelligence, money isn't everything. Even if a logistics company can afford to implement and maintain AI solutions, as well as to train its employees, this technology requires adjusted business models, processes, and the right mindset to deliver the digital transformation the sector is craving. Just like any other domain, the logistics industry has to stop relying on experiences and leverage the power of big data alongside real-time and forecast insights. If that is something you are willing to do, we predict that you are off to a bright future.

And if on your way up there you need a reliable and trustworthy partner who can guide you through the process, contact us! We're adept at business intelligence and artificial intelligence services and know just the way to be of help to you.

Valuable Insights

There are numerous ways to answer the question “How to use AI in logistics?”. The ultimate purpose of AI in transportation and logistics is to streamline operations across the industry, starting from customer service and demand forecasting to warehouse automation and delivery route optimization. If you want to get a deeper understanding of how to apply artificial intelligence in logistics, DHL is a great company to study.

Overall, the role of artificial intelligence in logistics is versatile, and you can utilize this technology in numerous sectors. For example, applications of AI in logistics include healthcare, where real-time route tracking can assist with elevating the security of medical supplies carriage; the retail field will equally benefit from machine learning algorithms, as they have the capability to optimize inventory levels across thousands of stores and scale warehouse efficiency; it is even possible to apply artificial intelligence in military logistics. AI in military logistics helps improve resource allocation and medical aid.

Chances are you've heard of gen AI in logistics. This content producing technology works tremendously well with other AI kinds, like conversational AI (ChatGPT), automation AI (robotics), predictive AI (analytics), etc. This technological mixture allows not only logistics but a wide variety of other fields to benefit from modern innovations through enriching data quality.

AI helps to manage demand volatility, production scheduling, resource allocation and distribution. It can automatically replenish inventory, identify anomalies, mitigate risks, and assist with equipment maintenance. AI is a great tool to automate routine tasks, reduce human error, and streamline the workflow that consists of operations with numerous manufacturers and suppliers.

All in all, AI in supply chain enhances the efficiency and quality of operations and increases employee and customer satisfaction.

The use of AI in the logistics industry has many benefits. As good as it feels, it does come at a price if a company doesn't prepare well. Surely, AI maximizes resources, but the costs of AI implementation and maintenance, as well as employee training, are high. Data exposure (even for the purpose of analysis) inevitably leads to concerns around privacy and security. Additionally, an organization has to obtain the right mindset and business processes prior to launching the shift, as artificial intelligence will not coexist with hidebound business models and outdated knowledge.

It is bright! The AI in logistics market size valued at USD 7.96 billion in 2022 is to reach USD 238.89 billion by 2031, growing at a CAGR of 45.93% during the forecast period (2023–2031) (Straits Research).

Contacts

Feel free to get in touch with us! Use this contact form for an ASAP response.

Call us at +44 151 528 8015

E-mail us at request@qulix.com